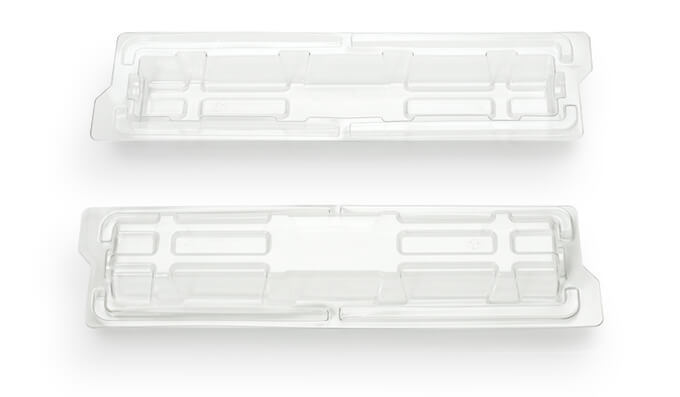

Thermoformed plastic shipping trays are an ideal solution for packaging all types of products. Not only do plastic shipping trays provide superior product protection they often simplify the packing process and make it easier to achieve exact counts per case.

Custom Design

Most shipping trays are custom designed and manufactured to your exact specifications with the most commonly used materials being PVC, PETG and PET. Shown here is a custom tray used to package PVA brushes for the microelectronics industry. Notice the reciprocal snap-perimeter design allowing the plastic tray to snap to itself when placed in an opposing position forming an excellent seal.

"The combined elements of all features results in a shipping tray, which then forms a shipping container keeping the product free of dust and debris."

- Thermoformed Products Manager, VisiPak

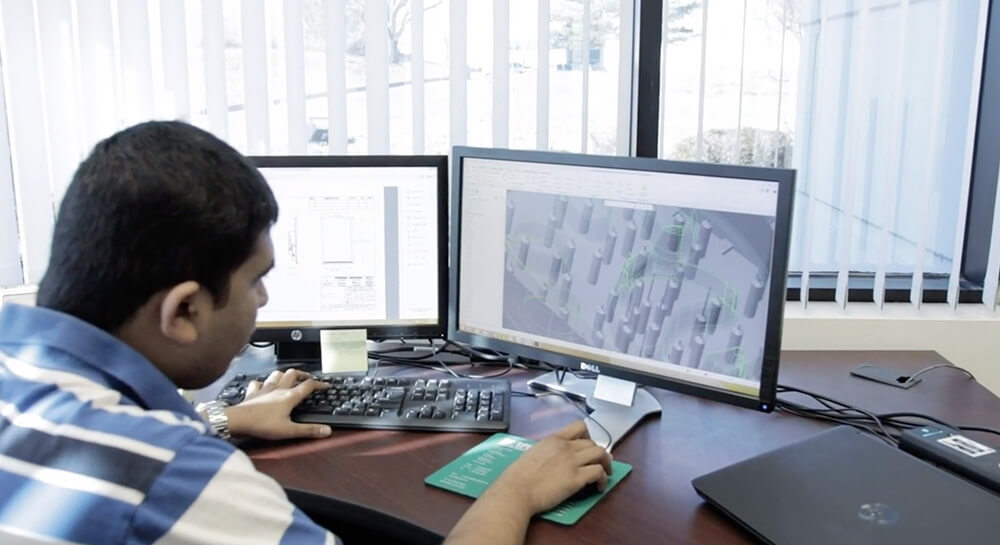

Rapid Prototyping

With extensive experience designing thermoformed shipping trays and comprehensive prototyping capabilities, our design team can quickly turn your conceptual designs into tangible prototypes, so you can get your product to market faster and more cost-effectively.

- 3D and 2D Computer Aided Design Software

- Start of the Art 3D Laser Scanners

- 3D MicroScribe Digitizing Equipment

- CNC Mold Milling Machine

- 3D Printers for Precise Model & Sample Generation

Better for the Environment?

In a world where most of us want to minimize our environmental footprint and employ the concepts of reduce, reuse and recycle, thermoformed shipping trays can help.

- Shipping trays also allow for a greater packing density which reduces in the number of cases being shipped.

- Shipping trays reduce or eliminate the need for loose fill packing materials

- Shipping trays can be reused especially when transported between facilities that are relatively close in geography.

- Plastic shipping trays are generally very easy to recycle

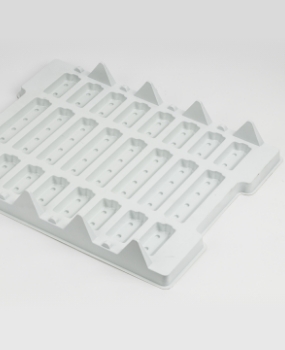

Manufacturing

Once your plastic shipping tray is designed, you can rest assured that it will be manufactured with quality and efficiency in our ISO 9001:2015 Certified facility featuring high-speed inline thermoformers.

- ISO 9001:2015 Certified Facility

- Cleanroom Manufacturing Options

- Extensive Production Capacity

- Consistent Quality

- U.S. Based Production

Custom Shipping Tray Gallery

SMP

ITW Rippey

Asco Valve

Shorr GPS

Electrical Components Mfr.

Magnet Manufacturer

Electrical Components Mfr.

PCB Fabricator

Wafer Fab Mfr.

Precision Parts Mfr.

Precision Parts Mfr.

Industrial Parts Mfr.

Optics Mfr.

Auto Parts Mfr.