Containers

Clear plastic containers by VisiPak are comprised of a versatile line of tubes, caps and closures. Mix and match a variety of options to create the ideal packaging tube container for your application. Just follow these easy 1-2-3 steps to get the most amazing clear plastic container package!

Step 1: Pick a Size & Shape

- Round tubes from 3/16" to 5"

- Unlimited lengths with no tooling

- Rectangles, squares, ovals & triangles

Step 2: Pick a Bottom

- Flexible PermaSeal

- Rigid PermaSeal

- Multiple Closures

Step 3: Pick a Top

- Caps and Plugs

- Multiple Hanging Options

- Many Styles and Colors

Step 1Pick a Size & Shape

VisiPak offers the industry’s most extensive line of clear plastic packaging tubes in 5 popular shapes – all available in virtually unlimited lengths with no tooling charges.

Step 3Pick a Top

21 Unique Styles

From clear plastic hanger plugs to friction-fit vinyl closures, our selection of tops is second to none. Plus, if you want a special size or style, we can make it. Any of these choices compliment the tube creating a unique clear plastic container package.

Poly Plugs

Poly Caps

Hanger Plugs

Hanger Caps

Vinyl Caps

Additional Options

Note, not every style cap or plug fits each tube.

When visiting the tubes page, a chart will display an "X" in the column indicating which caps or plugs are available for each tube size.

Decorating & Labels

To complete your package, our design team can print your tubes on our full-color presses, apply labels on our high speed equipment or assist with sourcing other graphics or shrink bands so your clear plastic container package stands out in a crowd.

Decorating & Security Options

- Custom cap and plug colors

- Silkscreen printing

- Labeling

- Pad printing

- Shrink sleeves/Bands

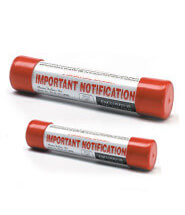

Specialty Packaging Tubes & Containers

Over the years our clear plastic containers have been an excellent source for specialty packaging. As demand grew for specific types of tube packaging, VisiPak developed product lines of clear plastic tubes specific to the growing industries, making it easier for the consumers. For added convenience most of these are available for online purchase.

Mailing Tubes Increase response rates on direct mail pieces.

Donation CansClear plastic containers with coin-slot tops.

Golf Ball TubesPrint your artwork directly on the tube.

Party Favor TubesShow off the candy with clear packaging titles.

Threaded ContainersAdd threads to a clear tube.

Ideal for All Types of Merchandising

VisiPak tube packaging and containers are as versatile as they are attractive. They can be designed to hang on a wall, stand on a shelf or fill a POP display.

Prohm-tectPOP Display

See how Prohm-tect combined a PermaSeal clear plastic container tube with multiple colors of vinyl friction fit caps that not only made the display pop, but quickly identified the products in the display by the Formula specified.